Shipping calculator

Payment methods

Product details

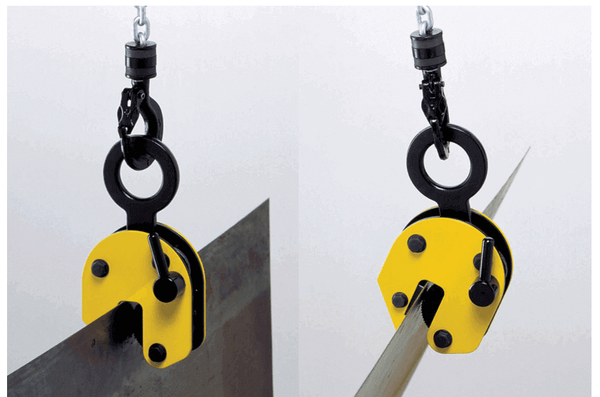

Camlok Lifting Clamp: Vertical Plate Clamps with Safety Lock

Lifting Clamps are one of the most important pieces of equipment in many lifting and material handling operations. No matter if it is in the manufacturing or construction process, lifting clamps serve a critical function such as lifting and moving a flat plate, rolled stock and beams.

These Camlok vertical plate clamps are primarily used for transporting sheet metal and steel plates in the vertical position, as well as lifting and rotating through 180 degrees.

They can also be used for transporting steel constructions and profiles. It is recommended to use a pair of plate clamps in conjunction with a spreader beam for a long plate.

Functions:

- The jaw is opened and closed with the locking lever, except for the ones with a capacity of 500KG which use a positive spring-loaded cam.

- The safety lock spring loads the cam jaw, preventing the clamp from opening even when there is no load on the jaw.

Uses:

- For lifting long plates (2 clamps and a lifting beam must be used)

- For lifting short plates (a single clamp can be used)

- For lifting plates from the horizontal to the vertical position and vice versa through 180 degrees

Fast & International Delivery now. For any inquiries, please contact us via Chat.

Operating Manual - Plate Clamp Safety

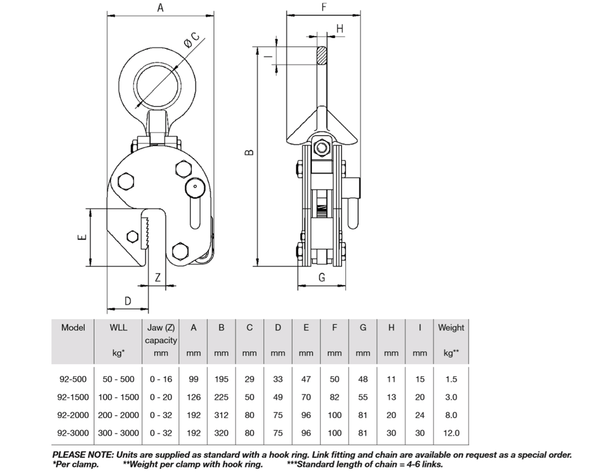

Specifications:

-

Capacity: 50kg - 20000 kg

Heavy-duty vertical plate clamps are also available - Jaw Capacity: 0 - 32mm max.

- Weight: 1.5 - 12kg

How to use Vertical Plate Clamps safely?

Before Lifting

-

Inspect the plate and clamp

- Based on operating manual -

Position the clamp:

- Place the clamp over the load centre of the plate. If the plate is long, use two clamps in conjunction with a spreader beam.

- Care must be taken to ensure no one clamp takes more than its SWL.

- Put the clamp onto the plate as far as it will go

- Place the fixed jaw onto the plate and turn the lever to the 'LOCK' position

- Check correct fitting and position before lifting

After Lifting (Release the plate & clamp)

-

Place down the load gently

- Do not lower quickly onto the floor -

Ensure the lifting sling is sufficiently slack

- In order to allow the hook-ring to be pushed down into the shell. -

Push the hook-ring down into the clamp body

- While turning the locking lever - Release the lifting clamp

Applications of Vertical Plate Clamps:

- Wind Power Energy

- Offshore

- Ship & Yacht Construction

- Tank & Vessel Construction

- Construction

Others:

- The surface hardness of the material must not exceed HRC 30/Brinell 300.

- Please read the Operating Manual carefully before use

- Safety Webinar by CM :